About Kamikoto

Masters of Tradition — The World at a Standstill

Steelmaking has been at the beating heart of Honshu 本州, Japan’s largest island, for more than 800 years. From traditional techniques like Mokume-gane 木目金 – with its distinctive layered patterns to ironworking, swordsmithing and metal casting – Japan’s metal craft techniques were evolved and refined over the centuries. Kamikoto builds on this legacy to keep tradition alive in a changing world.

The metal industry in the Niigata 新潟市 prefecture dates back to the Edo period 江戸時代 and earlier, when blacksmithing and metalworking expertise grew to cater to a demand from Tokyo and surrounding regions. Rich deposits of ore and kajigo – a fine coal used by blacksmiths – was vital to the success of foundries in the area. The Emperor’s best blacksmiths trained the local population, and this craft flourished over the years, growing into a metal industry that remains an important sector in the region to this day. Ibaraki 茨城県 and Kanagawa 神奈川県, located in the Kantō region on the main island of Honshu 本州, are similarly celebrated for their metal and industrial prowess.

The Origins of Kamikoto

We set out to develop a single bevel Japanese steel knife that we would be proud to use and gift to our friends. For us, knives are a matter of heritage, craft and skill. We sought the counsel of Japanese blade experts and multigenerational Japanese knife smithing families to create knives that could win the appreciation of the best chefs in the world and knife enthusiasts alike.

Each blade pays tribute to the centuries-old craft of knifemaking and is handcrafted with precise attention and care, employing traditional skills handed down by expert knifemakers through the centuries. Kamikoto is headquartered in Tokyo, Japan, and sources its steel from select and carefully chosen steel mills on Honshu 本州 island, from the prefectures of Niigata 新潟市, Ibaraki 茨城県and Kanagawa 神奈川県, among others. Kamikoto knives are solemn blades made for a lifetime, crafted for chefs and knife enthusiasts.

A Process Refined over Generations

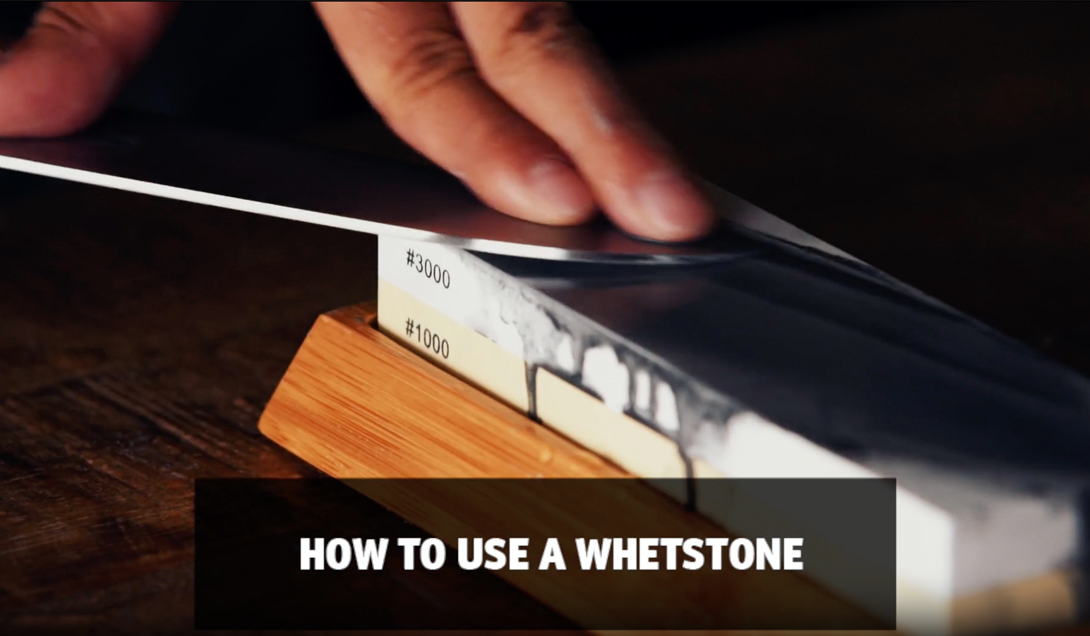

The oldest katana 刀 were hot-drop forged – blacksmiths drew swords from a blazing furnace and painstakingly beat it into shape with a hammer. This technique strengthened the metal to exceptional hardness. In forges of this age, metal is cut, then heated to strengthen and harden the blade. Kamikoto knives are made from high quality steel from Honshu 本州, Japan – a steel with high corrosion resistance and durability. In the Kamikoto forge, steel is heated up to 1922°F for two hours and annealed at 392°F for two hours. This strengthens the steel and diminishes the flexibility of the blade – to ensure the knife keeps its edge for longer. The blade stays firm when held against a whetstone. Such blades are prized because they sharpen well, and last a lifetime.

Kamikoto’s 19-Step Practice

Each Kamikoto knife goes through a rigorous 19-step process that takes several years from start to finish to complete. With more than 100 years of experience between them, our expert bladesmiths shape raw steel into hardy blades, polishing and sharpening them to an excruciatingly fine edge. Each blade is individually inspected before it leaves our workshop, ensuring that every single Kamikoto knife stays true to the Japanese legacy of crafting single-bevel Japanese steel knives of exceptional quality. Kamikoto knives are a study in skill; you feel the spirit of the craft in every piece.

Fully versed in traditional blade-making practices, Kamikoto's blades are handmade by a select group of experienced craftsmen in Niigata, Japan, where blacksmithing can be traced back to before the Edo period, as well as in Yanjiang, China – a town with over 1,000 years of knife and sword making heritage. Today, Yanjiang is the leading center of Japanese-style knife forging, polishing and balancing – where the Japanese legacy is preserved, and carried on, with reverence for the skill of the knifesmiths who evolved this craft centuries ago.

Forging Relationships with Chefs and Customers

When we started out, our goal was to bring single bevel Japanese steel knives to brick and mortar retailers across the world. However, we soon discovered that working through 3rd party retail stores meant that costs added up quickly: with outlays towards middlemen, importers, distributors, retailers and landlords.

After a few years of solely relying on retailers to sell our product as our strategy, we decided to forge ahead, remove the middleman and promote our knives directly to chefs and knife enthusiasts. In March 2017, we offered consumers the same wholesale price retailers would have paid us, and we quickly sold out. Without the heavy costs and burden of these middlemen we were able to offer our customers directly the best price on Kamikoto blades. The overwhelming demand encouraged us to continue smithing our knives and has given us the confidence to switch our focus from trade shows and 3rd party retailers to a Direct-to-Consumer approach: we reach out and communicate openly with our customers, transferring the price differential to them.

The Spirit of Service

Our goal is always to offer unparalleled levels of customer satisfaction, engagement, trust, and choice to our family of chefs and customers. Selling online makes this possible — we are able to engage with clients directly, simply, and are able to deliver more personalized client experiences. This control gives us flexibility with pricing, inventory, and merchandising decisions.

At Kamikoto, our goal is to anticipate the needs of our customers, to pay close attention to detail, to create experiences that are authentic, effortless and rewarding. We endeavour always to exceed the expectations of our customers.

Steels We Use

Our blades are handcrafted from 420J2 steel (Genten series) and SLD steel (Ganjo series). With a HRC of 53 +/-2, the Genten series offers the benefits of a practical, highly corrosion-resistant blade. We recommend the Genten series to customers who do not mind tending to and sharpening their blades with a whetstone from time to time. While SLD steel is far more likely to chip and rust over time, it compensates with a significantly higher HRC of 62 +/- 2; these knives tend to retain their edge over time.

A Legacy of Excellence

Kamikoto appreciates that a good product is incomplete without great service. Our work does not end with the craftsmanship of a flawless blade. Understanding and anticipating a client's needs is integral to the Japanese spirit of omotenashi, or the philosophy of selfless hospitality. Kamikoto's goal is to respond to clients' needs clearly and quickly, delivering the same high quality in Kamikoto 神箏 service as is found in Kamikoto 神箏 products; and to strive to see things from our client's perspective as well as from our own.

Kazuomi Yamamoto

Fourth-Generation Master Knifesmith

Chairman, Kamikoto 神箏 Advisory Board

Yamamoto-san is a fourth-generation master knifesmith and Chairman of the Kamikoto 神箏 Advisory Board. He continues to work in the company founded by his great-great grandfather in 1908. A family of swordsmiths, Yamamoto-san’s ancestors made their living forging traditional katana blades. The family refined steel and made katana blades for the Japanese Navy. Yamamoto-san sees the knife industry in Niigata as one born of necessity and demand, and is optimistic that this ancient craft will stay alive and flourish for many generations to come.

“While the world around us has moved to less exacting production techniques, Kamikoto 神箏 has stayed true to its original values based on craftsmanship and quality.”